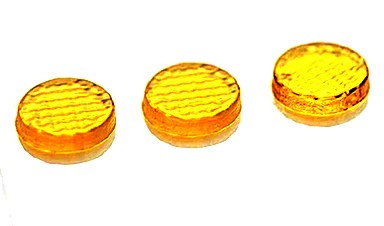

A brand new method for 3D printing remedy has enabled the printing of a number of medication in a single pill, paving the best way for personalised drugs that may ship timed doses.

Researchers from the College of Nottingham’s, Centre for Additive Manufacturing have led analysis alongside the Faculty of Pharmacy that has fabricated personalised medication utilizing Multi-Materials InkJet 3D Printing (MM-IJ3DP). The analysis has been printed in Supplies At the moment Advances.

The workforce have developed a cutting-edge methodology that allows the fabrication of personalized pharmaceutical tablets with tailor-made drug launch profiles, guaranteeing extra exact and efficient therapy choices for sufferers.

Utilizing Multi-Materials InkJet 3D Printing (MM-IJ3DP), tablets will be printed that launch medication at a managed price, decided by the pill‘s design. That is made attainable by a novel ink formulation primarily based on molecules which are delicate to ultraviolet mild. When printed, these molecules kind a water-soluble construction.

The drug launch price is managed by the distinctive inside construction of the pill, permitting for timing the dosage launch. This methodology can print a number of medication in a single pill, permitting for complicated remedy regimens to be simplified right into a single dose.

Dr. Yinfeng He, Assistant Professor within the College of Engineering’s Centre for Additive Manufacturing led the analysis, he mentioned, “That is an thrilling step forwards within the growth of personalised remedy. This breakthrough not solely highlights the potential of 3D printing in revolutionizing drug supply but in addition opens up new avenues for the event of next-generation personalised medicines.”

“Whereas promising, the expertise faces challenges, together with the necessity for extra formulations that assist a wider vary of supplies. The continued analysis goals to refine these features, enhancing the feasibility of MM-IJ3DP for widespread software,” Professor Ricky Wildman added.

This expertise will probably be significantly helpful in creating remedy that should launch medication at particular occasions, making it perfect for treating illnesses, the place timing and dosage accuracy are essential. The flexibility to print 56 drugs in a single batch demonstrates the scalability of this expertise, offering a powerful potential for the manufacturing of personalised medicines.

Professor Felicity Rose on the College of Nottingham’s Faculty of Pharmacy was one of many co-authors on the analysis, she says, “The way forward for prescribed remedy lies in a customized strategy, and we all know that up 50% of individuals within the UK alone don’t take their medicines appropriately and this has an influence on poorer well being outcomes with situations not being managed or correctly handled. A single capsule strategy would simplify taking a number of drugs at totally different occasions and this analysis is an thrilling step in direction of that.”

Extra data: Geoffrey Rivers et al, Enabling high-fidelity personalised pharmaceutical tablets by means of multimaterial inkjet 3D printing with a water-soluble excipient, Supplies At the moment Advances (2024). DOI: 10.1016/j.mtadv.2024.100493

Supplied by College of Nottingham

CP PLUS 2MP Smart Wi-fi CCTV Camera | 360° & Full HD Home Security | Full Color Night Vision | 2-Way Talk | Advanced Motion Tracking | SD Card Support (Upto 256GB) | IR Distance 20Mtr | EZ-P21

₹1,199.00 (as of May 14, 2024 14:12 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)OnePlus 12R (Iron Gray, 16GB RAM, 256GB Storage)

₹45,999.00 (as of May 14, 2024 14:12 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)boAt Airdopes 141 Bluetooth TWS Earbuds with 42H Playtime,Low Latency Mode for Gaming, ENx Tech, IWP, IPX4 Water Resistance, Smooth Touch Controls(Bold Black), in Ear

₹1,299.00 (as of May 14, 2024 14:12 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Oneplus Nord CE4 (Celadon Marble, 8GB RAM, 128GB Storage)

₹24,999.00 (as of May 14, 2024 14:12 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Samsung Galaxy M34 5G (Waterfall Blue,6GB,128GB)|120Hz sAMOLED Display|50MP Triple No Shake Cam|6000 mAh Battery|4 Gen OS Upgrade & 5 Year Security Update|12GB RAM with RAM+|Android 13|Without Charger

₹13,999.00 (as of May 14, 2024 14:12 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)FUR JADEN Anti Theft Number Lock Backpack Bag with 15.6 Inch Laptop Compartment, USB Charging Port & Organizer Pocket for Men Women Boys Girls

₹649.00 (as of May 14, 2024 14:12 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Lapster 24pcs Mix Spiral Charger Spiral Charger Cable Protectors for Wires Data Cable Saver Charging Cord Protective Cable Cover

₹99.00 (as of May 14, 2024 14:12 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Oakter Mini UPS for 12V WiFi Router Broadband Modem | Backup Upto 4 Hours | WiFi Router UPS Power Backup During Power Cuts | UPS Broadband Modem | Current Surge & Deep Discharge Protection

₹1,099.00 (as of May 14, 2024 14:12 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)REXERA Portable Rechargeable Neck Fan 20Hrs Play 9000mAh USB Charging Battery Bladeless Neck Fan Smart Mini Hand Free 3 High Speed Fan Low Noise 360° Cooling FAN (Battle Green)

₹690.00 (as of May 14, 2024 14:12 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Canon PIXMA PG47 Black Ink Cartridge

₹667.00 (as of May 14, 2024 14:12 GMT +00:00 - More infoProduct prices and availability are accurate as of the date/time indicated and are subject to change. Any price and availability information displayed on [relevant Amazon Site(s), as applicable] at the time of purchase will apply to the purchase of this product.)Auto Amazon Links: No products found.