Area Science: The just lately launched Cygnus NG-20 robotic spacecraft is presently docked with the Worldwide Area Station (ISS). The resupply mission is filled with provides for the ISS crew in addition to science experiments, together with an progressive 3D metallic printer developed by Airbus for the European Area Company (ESA).

In a historic growth, the ISS is now outfitted with a 3D printer able to theoretically shaping new objects by melting stainless-steel wire. This experimental printer, designed by Airbus and ESA, serves as a way to check and deal with the technical challenges related to metallic 3D printing in house. It holds the potential to supply astronauts on future house exploration missions with progressive resilience and self-sustainment capabilities.

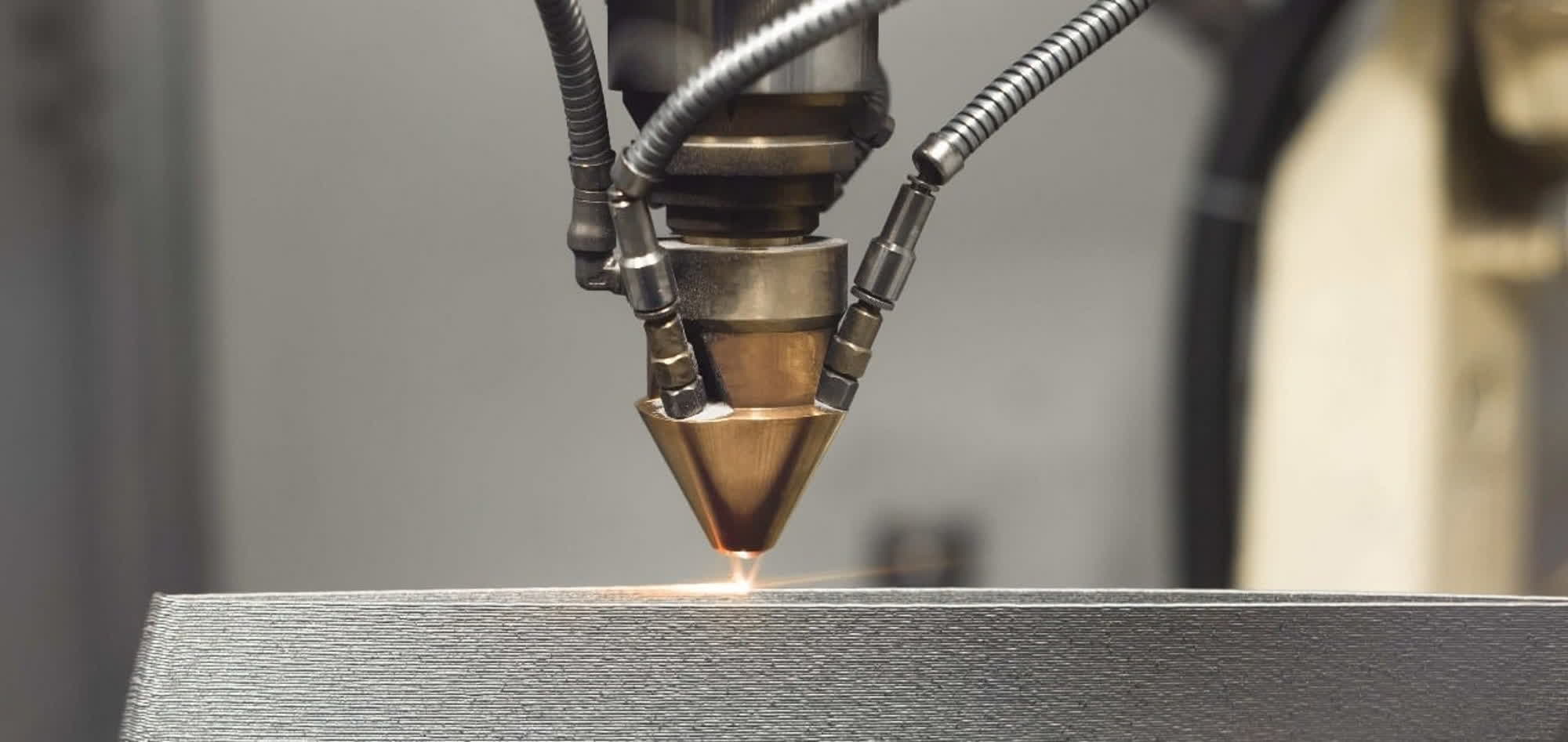

The 3D printer makes use of an industrial course of often called additive manufacturing, one which has already revolutionized the design of elements and objects on Earth. Whereas the ISS has a number of 3D printers utilizing plastic materials, metallic printing presents totally different challenges, requiring a laser to succeed in the melting level of chrome steel (1,400 levels Celsius), in comparison with the 200 levels Celsius wanted for plastic wires.

Guaranteeing the security of the crew and the station is paramount, the ESA emphasised, requiring correct warmth and fumes recycling. The printer operates inside a completely sealed field, and the inner oxygen environment should be changed by nitrogen throughout printing to stop oxidization of the metallic elements being printed.

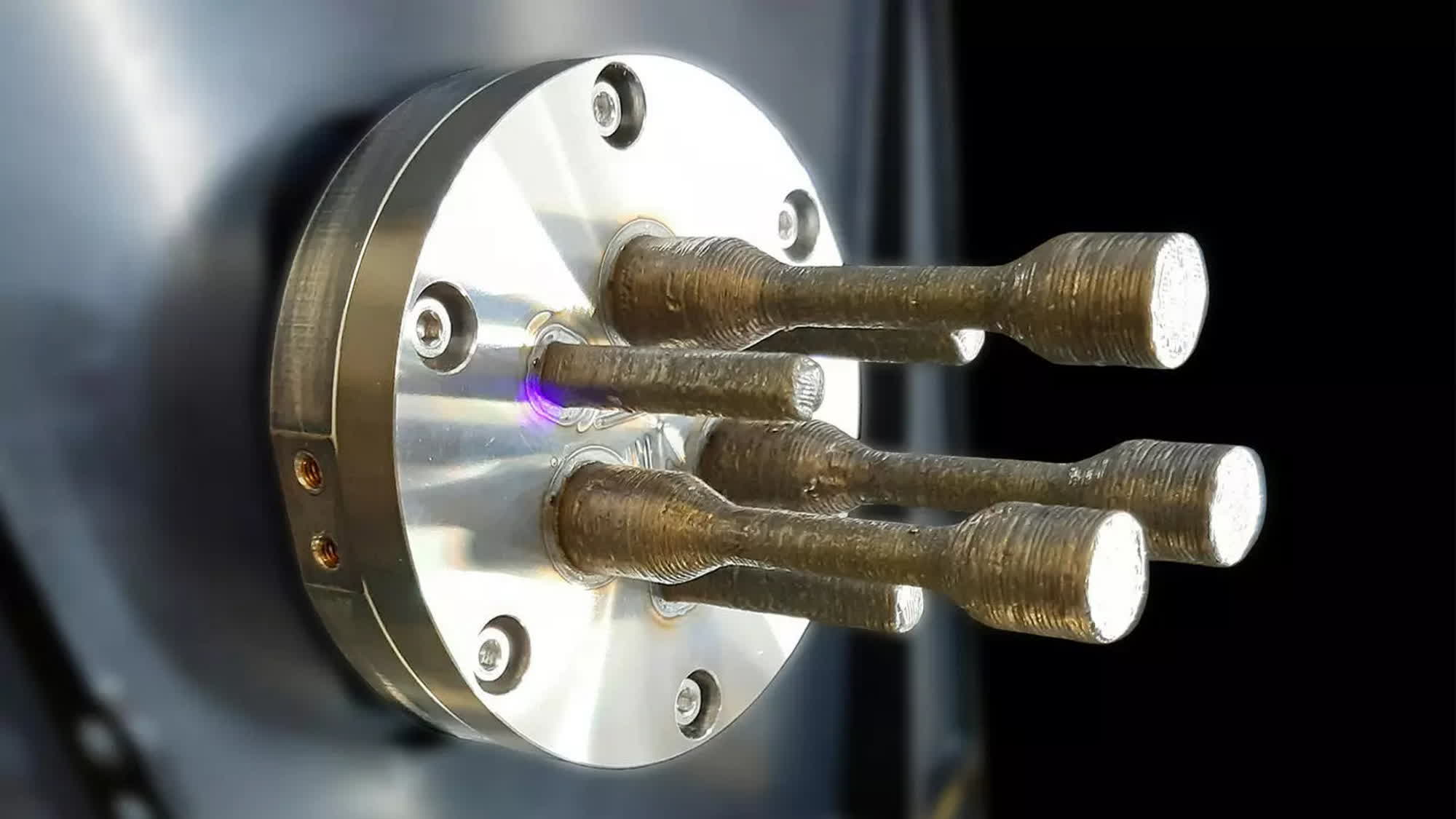

As soon as every thing is up and operating, the experimental machine will print “4 fascinating shapes” to check the printing course of’s efficiency in microgravity circumstances. The 4 designs are smaller than a soda can, weigh lower than 250 g, and can take two to 4 weeks to print. The printer will function on a schedule, as its followers and motors are “comparatively noisy,” we’re advised.

The ultimate printed merchandise will then be saved and returned to Earth, the place they are going to be in comparison with reference prints created on the bottom. Scientists will study how the house surroundings can have an effect on the printing course of, offering invaluable insights into how the know-how may be improved to turn into an built-in a part of future house missions.

Tommaso Ghidini, head of the mechanical division on the ESA, said that the chance to print metallic elements in house is a “promising functionality” that may help the way forward for house exploration – on the ISS and “past.” Because of in-situ manufacturing, astronauts may sooner or later restore or increase house buildings on otherworldly settlements just like the Moon or Mars, eliminating the necessity to look ahead to expensive, prolonged shipments of spare elements from Earth.